FEASIBILITY STUDY IN INDUSTRIAL VISION: THE FIRST STEP TOWARDS A RELIABLE AND HIGH-PERFORMING SOLUTION

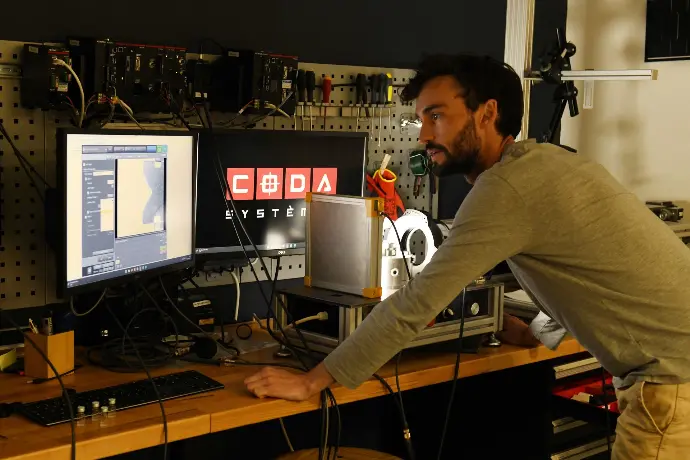

Before integrating an industrial vision system, it is essential to validate the technical and economic feasibility of the project. At CODA Systems, this validation is based on a rigorous approach, conducted in our state-of-the-art laboratory and, if necessary, directly on your site. Thanks to our expertise, our commitment to results, and a proven testing protocol, you benefit from a customized solution tested in real conditions.

OUR SUPPORT

Do you have an identified need in quality control? Rely on a structured and reliable approach to secure your project from the very first steps. With our feasibility study, you benefit from a precise and realistic analysis based on concrete tests in the laboratory and, if necessary, on-site. A solid foundation to build an effective solution tailored to your field constraints.

A STRONG COMMITMENT TO RESULTS

At CODA Systems, our approach is based on a commitment to results: if we validate the feasibility of a project, it is because we are confident that we can achieve the objectives defined with you.

Our innovative validation protocol ensures the proper differentiation between compliant products (OK) and non-compliant products (NG), even in the presence of product or environmental variations. This reliability requirement is at the heart of our approach.

A COMPREHENSIVE STUDY CONDUCTED BY EXPERTS

Our feasibility study aims to determine whether the proposed solution can operate effectively in your production environment. This preliminary phase allows for:

- Validate the detection of defects and/or the dimensional measurement of components.

- Identify the right lighting, optics, and image processing parameters.

- Test several possible configurations to optimize cost/performance.

- Ensure the reliability of results through strict validation protocols (R&R, Cmc…).

We are committed to providing you with a solution that truly works — not just a simple simulation, but a concrete proof of performance.

A HIGH PERFORMANCE LABORATORY

Our laboratory is specifically designed to replicate real production conditions. Ambient lighting, vibrations, types of materials, production pace… every factor is taken into account to ensure tests that are representative of your field constraints.

We have comprehensive equipment to cover a wide range of applications:

- Industrial cameras of different resolutions and technologies (Keyence, Omron, Cognex, etc.)

- Various optical objectives

- Precision lighting systems

- Measuring machines and advanced image processing software

This diversity of tools allows us to tailor each test to the reality of your parts and your production line.

REAL-WORLD TESTING AND ON YOUR SITE

When production conditions are too specific to be simulated, our teams travel to conduct feasibility tests directly on-site. This hybrid approach (lab + field) allows us to ensure reliable results, regardless of the complexity level of your environment.

These on-site tests are also an opportunity to lay the groundwork for a POC (Proof of Concept), in order to quickly demonstrate the added value of a well-configured industrial vision system, without immediately going through a full integration.

POC PROJECTS & FEASIBILITY STUDIES

Examples of projects completed by CODA Systèmes

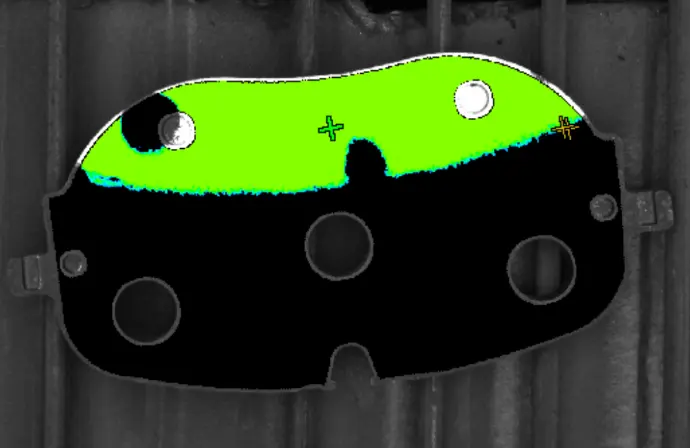

QUALITY CONTROL OF BRAKE PADS

The reliability of components, particularly those of the braking system, requires crucial importance. This is why the brake pads must exhibit impeccable quality to ensure the safety of users while adhering to the strict standards imposed by the industry.

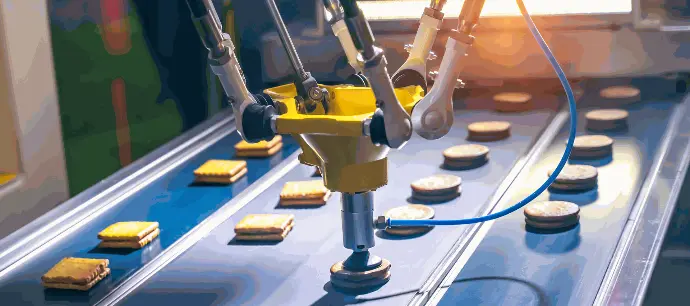

ONLINE 3D CONTROL OF COOKIES FOR A FOOD INDUSTRY PLAYER

Produced in industrial quantities, the cookies must have a uniform appearance to meet market requirements and customer preferences.

READ THE USE CASE

CONTROL OF APPEARANCE AND DIMENSIONAL OF REFRACTORY BRICKS

Capable of withstanding extreme thermal conditions, refractory bricks are subject to strict requirements in terms of reliability and efficiency..

SCRATCH CONTROL ON METAL BOXES FOR COSMETICS

In the world of cosmetics, where the added value of products is fundamental, consumer demands leave no room for error. A rigorous quality control is essential to ensure excellence and meet particularly high expectations..

ANY QUESTIONS?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA