INNOVATIVE INDUSTRIAL VISION

FOR AUTOMATED QUALITY CONTROL

WHAT IS INDUSTRIAL VISION?

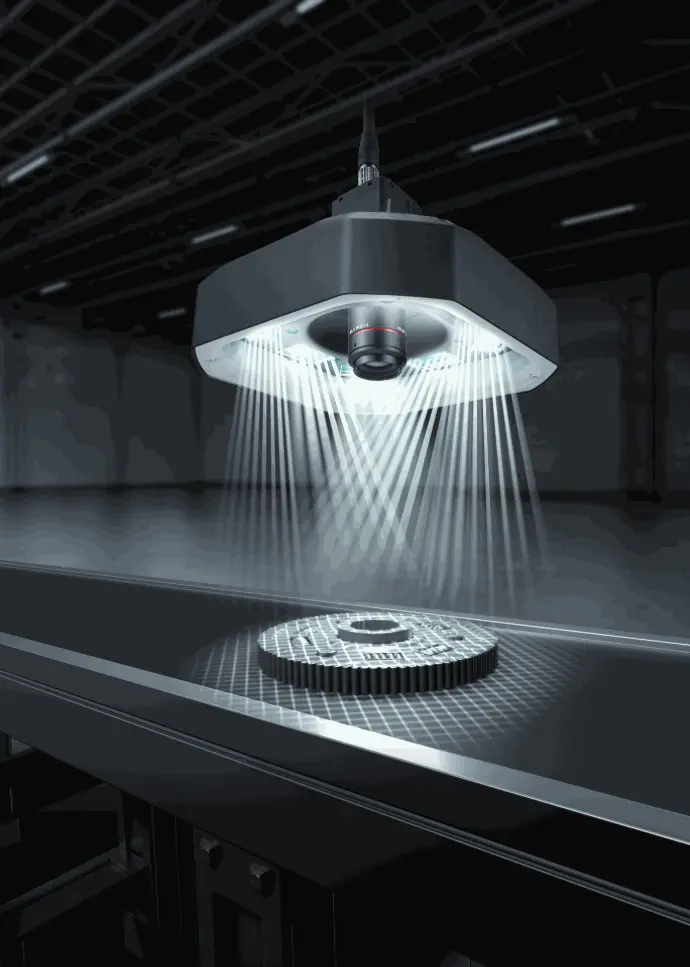

Industrial vision is at the heart of modern production processes, where the demands for quality and efficiency are becoming increasingly strict. It offers unmatched precision and speed for the inspection of objects and products.

In simple terms, industrial vision refers to the use of cameras, lighting, and image processing software to capture and analyze images within industrial processes. This technology enables machines to "see" and "understand" objects in their environment in order to make automatic decisions based on these observations. Whether it's to identify parts, measure their dimensions, or inspect finished products, industrial vision is an essential component of modern automated systems.

Thanks to industrial vision, companies can achieve levels of profitability that are impossible to obtain manually.

APPLICATIONS OF INDUSTRIAL VISION CONTROL

Our solutions are used in various fields to ensure a high level of quality:

- Industrial vision inspection to detect defects and verify the conformity of parts.

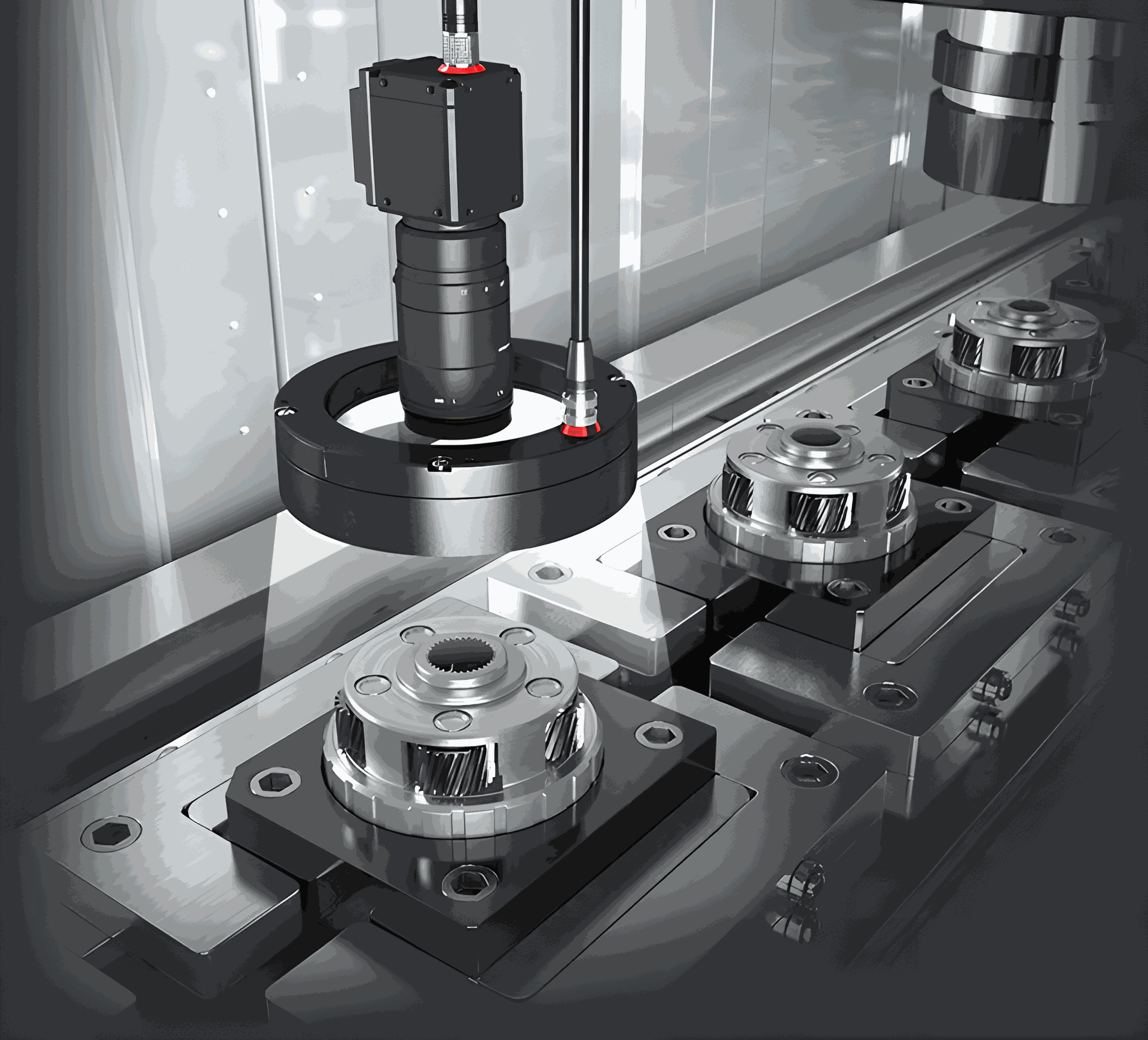

- Industrial measurement to control manufacturing dimensions and tolerances.

- Reading and verification of barcodes to ensure the traceability of parts.

- Precise identification and assembly of components using vision-guided robotics.

AND ARTIFICIAL INTELLIGENCE?

This new tool brings real advancements in the field of control: it is still necessary to know in what context to use it. AI is not an end goal but an additional means that complements the toolbox of vision engineers. At CODA Systèmes, we ensure that the use of this tool is indeed aimed at improving the quality and/or stability of the control solution and not just a simple sales argument.

To learn more, check out this article on our blog :

FROM CLASSICAL ALGORITHMS TO NEURAL NETWORKS: THE EVOLUTION OF ARTIFICIAL INTELLIGENCE

A PROJECT ?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA