INDUSTRIAL VISION EQUIPMENT:

HOW TO CHOOSE YOUR SOLUTION WELL?

The industrial vision camera has become a strategic pillar in production environments. It allows the quality control automation, improves traceability, and secures industrial processes. However, to reap all the benefits, it is essential to select a solution that meets one's needs, both in terms of hardware and software.

INDUSTRIAL VISION EQUIPMENT

We offer solutions in automated quality control, including equipment selection. At CODA Systèmes, we believe it is essential to ensure a smooth implementation at your production site, taking into account environmental and installation constraints. Our approach guarantees compliance with your specifications to address your challenges of compliance and reliability.

WHY INVEST IN AN INDUSTRIAL VISION CAMERA?

Industrial vision relies on the acquisition and automated processing of images. With an industrial vision camera or a laser profilometer, it is possible to perform quick, precise, and reliable inspections without interrupting the production flow. This type of technology allows :

- Detecting humans eyes invisible or inaccessible defects

- Reduce waste and avoid customer returns

- Increase repeatability and traceability

- Automate tedious or risky tasks

The automotive, pharmaceutical, agri-food, electronics, and packaging industries are among the sectors where industrial vision is now essential.

CHOOSE THE RIGHT EQUIPMENT, OUR EXPERTISE

The choice of a camera in industrial vision or a laser profilometer is not limited to comparing technical specifications. It depends on many parameters:

- Necessary resolution

- Processing speed

- Light conditions

- Type of parts to inspect

- Mechanical or environmental integration constraints

At CODA Systèmes, we do not impose any brand, which allows us to offer you the most relevant solution based on your objectives and constraints. We regularly work with recognized references such as Keyence cameras, but also with other trusted brands to cover all use cases.

WHICH IMAGING SYSTEM TO DEPLOY ?

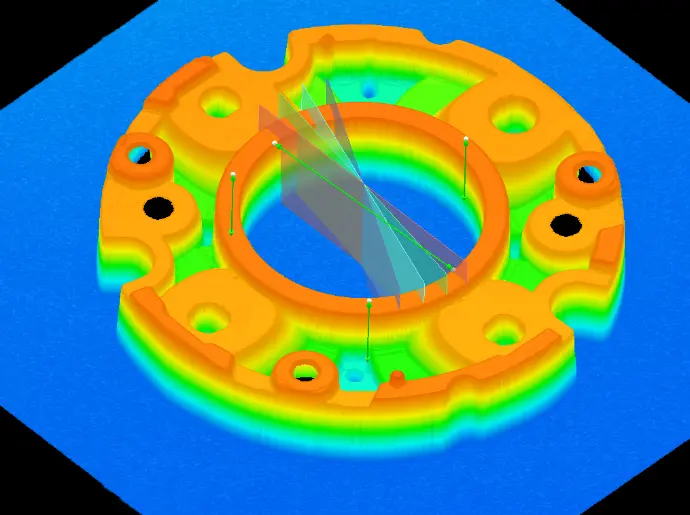

VISION 2D & VISION 3D

2D vision analyzes contrasts and flat shapes, while 3D vision using a laser profilometer allows for the precise capture of a part's topography. This technology is essential for measuring volumes, complex heights, or inclinations (such as the torque control of caps) with micrometric precision.

We help you define the optimal technology for your application :

- Matrix or linear cameras: For surface analysis, code reading, or appearance defect detection.

- Laser Profilometers (3D Vision): For complex dimensional checks, height measurement, or volume inspection, ensuring total reliability even on parts with variable geometries.

- High sensitivity and high-speed sensors: To meet the most demanding production rates.

CONCRETE APPLICATIONS OF INDUSTRIAL VISION CONTROL

The possibilities offered by industrial vision inspection are numerous: presence/absence control, dimensional or geometric inspection, defect detection, barcode reading, counting of elements.... Each application is tailored to your product, your pace, and your compliance criteria.

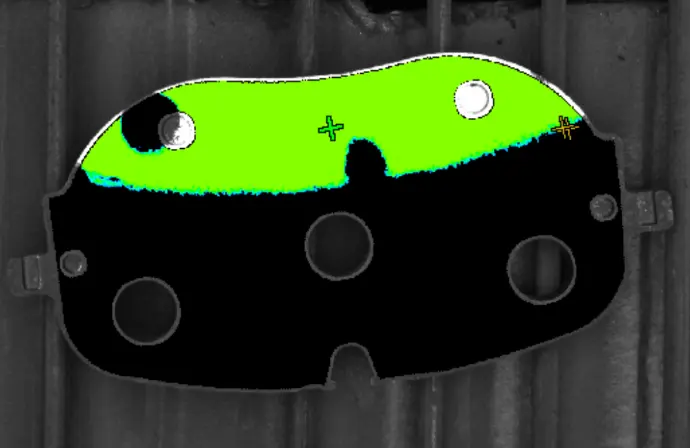

QUALITY CONTROL IN THE AUTOMOTIVE INDUSTRY

The reliability of the parts is paramount, especially for the braking system. It is crucial that the brake pads are of optimal quality to ensure the safety of users and to meet the strict requirements imposed by the industry.

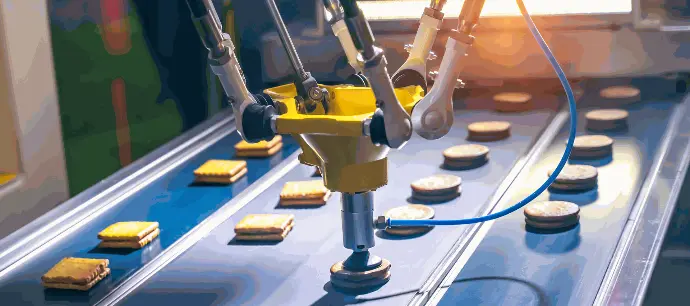

ONLINE 3D CONTROL IN THE FOOD INDUSTRY

The cookies, produced in large quantities, must have a uniform appearance to meet marketing criteria and satisfy consumer expectations.

AUTOMATED ASPECT AND DIMENSIONAL CONTROL

Designed to withstand extreme temperatures, refractory bricks must meet rigorous standards of quality and performance.

A PROJECT ?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT US