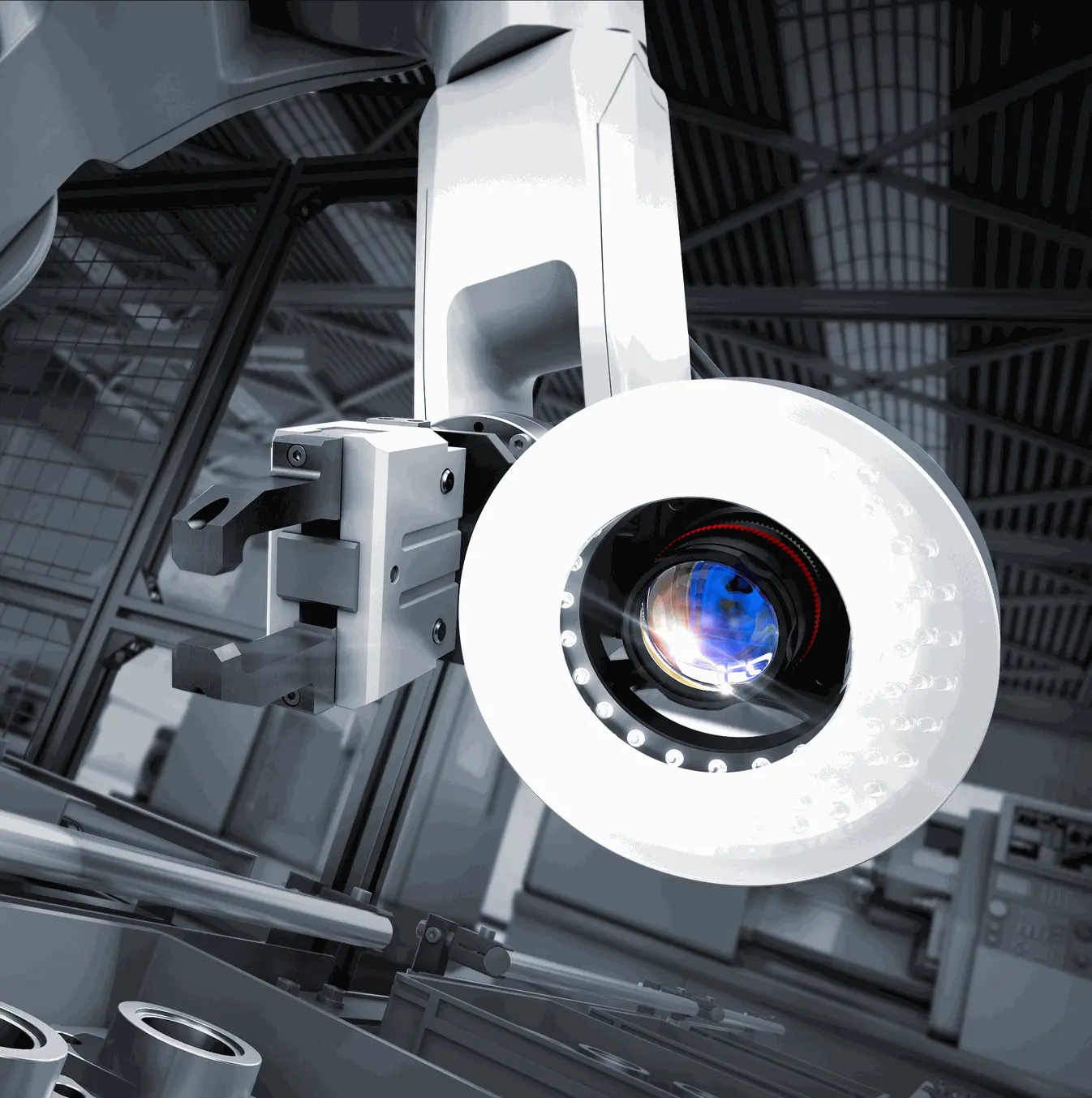

INTEGRATOR OF AUTOMATED CONTROL SOLUTIONS FOR INDUSTRY

QUALITY - PROCESS - SAFETY

PUTTING YOU AT THE HEART OF OUR FIELD OF VIEW

YOUR NEED

We take your expectations regarding industrial vision and measurement into account to provide you with the most suitable solution.

SOLUTIONS' CHOICE

Our team has extensive experience in selecting the systems, cameras, and lighting needed to meet your requirements.

THE SETTING UP

Thanks to our partners, we have access to a wide range of high-quality products, and we can support you throughout the purchasing and integration process of the solutions.

THE MAIN APPLICATIONS OF INDUSTRIAL VISION INSPECTION

The heart of inspection lies in the ability to process captured images. An effective industrial vision solution not only detects defects but also classifies them, tracks data, and interacts with other systems on the production line.

PRESENCE/ABSENCE

Check if all expected elements are present (e.g., cap on a bottle)

DIMENSIONAL CONTROL

Measure distances, diameters, thicknesses, or angles with great accuracy.

APPEARANCE CONTROL

Detect scratches, bubbles, stains, smudges, breaks, or any other visual anomalies.

MARKING CONTROL

Ensure that the printed information is correct, legible, and well-positioned.

READING CODES

Read and validate barcodes, datamatrix, or QR codes, often used for logistics tracking.

SETTINGS & MAINTENANCE

Identify the source of problems on your machines to optimize your production lines.

OUR REFERENCES

Discover all our projects in industrial vision by industry ➡️

THE IMPACT OF INDUSTRIAL VISION ON PRODUCTION PROCESSES

QUALITY CONTROL

Industrial vision systems are able to detect tiny defects on products with a speed and precision that the human eye could never match. For example, they can spot microscopic cracks on surfaces or tiny variations in colors, thereby ensuring that only products that meet specifications leave the production line.

PRODUCTION AUTOMATION

Industrial vision enables complex tasks automation such as as sorting, assembly, and parts quality control. The systems can read information such as 1D or 2D codes, guide robots, or sort objects based on their characteristics.

EFFICIENCYS’ IMPROVEMENT

Vision systems generate valuable data to optimize industrial processes. By analyzing this information, companies can identify opportunities to reduce waste, improve workflows, and increase productivity. The results obtained are repeatable and objective, thus avoiding errors due to human intervention.

CHOOSE THE INDUSTRIAL VISION SOLUTION THAT MEETS YOUR NEEDS WITH CODA

At CODA Systèmes, we support you according to your needs and your level of expertise, whether it involves a complete on-site integration or training on your systems to enhance your autonomy.

We understand the importance of selecting the right industrial vision system to optimize your operations. Our experts advise you on the different types of cameras (2D or 3D, area or line), assess your lighting needs (LED, lasers, infrared or UV light...), and guide you towards high-performance image processing software capable of effectively analyzing the generated images..

Finally, we take the time to train your teams through our training organization in industrial vision.

Our goal: to provide you with customized solutions tailored to your requirements and processes, in order to improve the quality, productivity, and reliability of your production lines..

FOLLOW OUR LATEST NEWS

A PROJECT ?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA