QUALITY CONTROL SOLUTIONS ADAPTED TO YOUR NEEDS

OUR CUSTOMIZED SOLUTION

At CODA Systèmes, we offer personalized support designed to adapt to your needs and your project's reality. From feasibility studies to equipment selection through real-world testing, and up to the training of your teams, we intervene wherever you need us. Our approach is field-oriented to ensure the success of your quality control projects.

FEASIBILITY STUDY & POC

In order to strengthen your investment in vision and measurement systems, we offer feasibility studies to validate equipment and integration choices.

SUPPLY OF MATERIAL

Following the conclusions of our study, we offer you the most optimized equipment for your project, which we source from the best suppliers in the market.

COMMISSIONING

We carry out complete commissioning on vision and measurement systems: integration, hardware adjustment, image capture, program development, reliability assurance, and testing.

INTEGRATION

In order to provide you a ready-to-use solution, we carry out the integration of vision systems into your industrial environment: mechanics, automation, electricity, HMI...

AUDIT

We conduct audits of your vision and measurement systems to assess their compliance, performance, and to ensure the reliability of your installations.

SUPPORT & MAINTENANCE

We offer maintenance contracts to ensure comprehensive support for systems through remote or on-site assistance in a timely manner.

TRAINING

We support companies in their skills development. Our organization provides training in vision and measurement for all levels.

TURNKEY PROJECT

Thanks to our partnerships with various integration providers, CODA can meet your "turnkey" needs including feasibility studies, vision equipment, integration, and associated services.

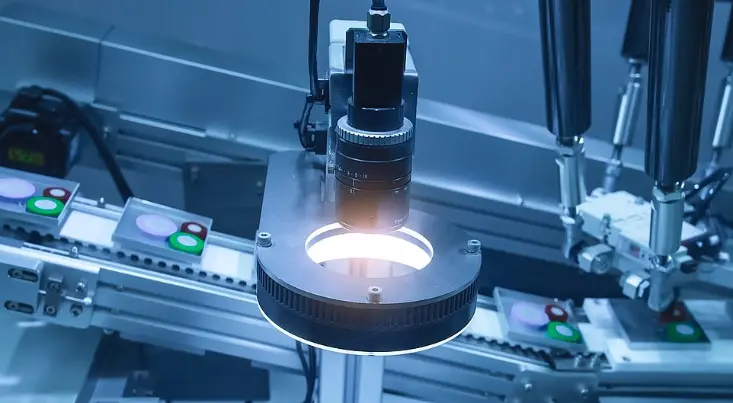

OUR INDUSTRIAL VISION CONTROL SOLUTIONS

Industrial vision inspection is a proven technology for ensuring the quality and compliance of products on production lines. To ensure the success of such a project, rigorous planning and methodical execution are essential.

Our mission is to simplify your journey in industrial vision by providing you understandable solutions tailored to your needs. Our expertise covers the entire process, from supplying innovative vision systems to supporting your teams through specialized training.

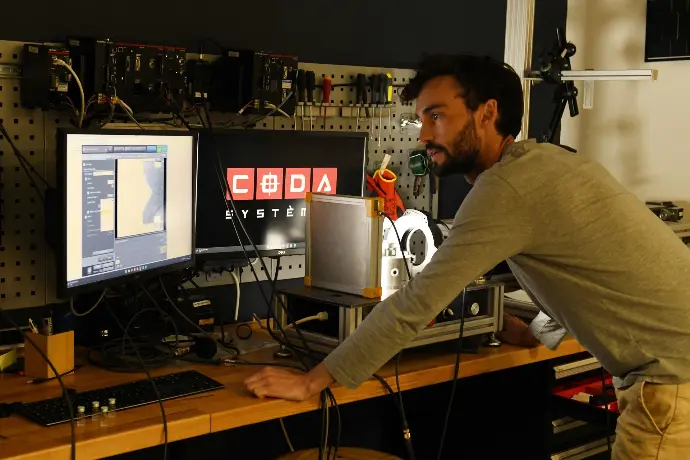

OUR LABORATORY

CODA has a laboratory within its premises equipped with vision systems, precision lighting, high-quality cameras, and measurement machines. Our laboratory is the place where ideas come to life and solutions take shape. It is here that our engineers test, optimize, and customize each component to provide you with tailored solutions. Our laboratory guarantees the discovery and validation of a solution suited to your needs..

WHY CHOOSE MACHINE VISION INSPECTION?

In an industrial environment where quality control and measurement precision are essential, the machine vision emerges as a solution to significantly reduce the risk of error, while adhering to strict standards and automating the verification processes.

THE KEY ADVANTAGES OF INDUSTRIAL VISION CONTROL

- Product quality improvement: Identification and correction of defects before shipping.

- Productivity gain: Real-time checks performed without interrupting production.

- Cost reduction: Less waste and a decrease in non-compliance expenses.

- Traceability and compliance with standards: Data analysis to ensure regulatory compliance.

- Flexibility and adaptability: Integration into various industrial environments.

The automation of quality control also improves the operators' productivity, who can focus on higher value-added tasks. Whether for unit inspection at the production line, precise measurement, or 100% online analysis, industrial vision systems represent a strategic advancement for optimizing industrial performance.

OUR TECHNOLOGIES FOR OPTIMAL CONTROL?

To ensure reliable and efficient control, we integrate cutting-edge technologies such as industrial vision cameras and advanced image analysis software. Our industrial vision systems are designed to adapt to any production environment.

Our solutions include:

- High-definition cameras and lighting to capture the smallest details

- Programs for image analysis and automating quality control

- A smooth integration with existing production systems, without disruption to the lines

- An intuitive user interface that facilitates the use of collected data

Whether for 2D or 3D inspections, vision or industrial measurement, our systems offer great flexibility and adapt to various production rates.

CONTACT US FOR A CUSTOM SOLUTION

Every industrial project is unique. Our experts are here to help you develop a machine vision control solution perfectly tailored to your needs. Contact us today for a personalized study and optimize the quality of your production with our customized support.