QUALITY CONTROL OF BRAKE PADS FOR AN AUTOMOTIVE PARTS MANUFACTURER

In the automotive industry, the reliability of components is essential, especially when it comes to the braking system. The quality of brake pads must be impeccable to ensure user safety and meet the industry's rigorous standards. In light of these requirements, an automotive parts manufacturer sought an advanced quality control solution to ensure 100% compliance at a key stage of its production.

THE CHALLENGE

The control of the application of the industrial adhesive underlayer on the brake pads represented a major challenge. A defect in this operation could compromise the adhesion of the lining, making the brake defective and posing a risk to users. Several constraints made this control particularly complex:

- Variety of references: many different brochures to inspect.

- Challenging industrial environment: pervasive dust, conveyor belt vibrations, and lack of contrast in captured images.

- Variable conditions: dry or wet parts, generating unwanted reflections.

- High cadence: inspection of a wafer every second, at a speed of 450 mm/s.

- Random position: no control over the angle and position of the plates on the conveyor.

Without a high-performance vision system tailored to these constraints, image analysis would have been unusable and ineffective.

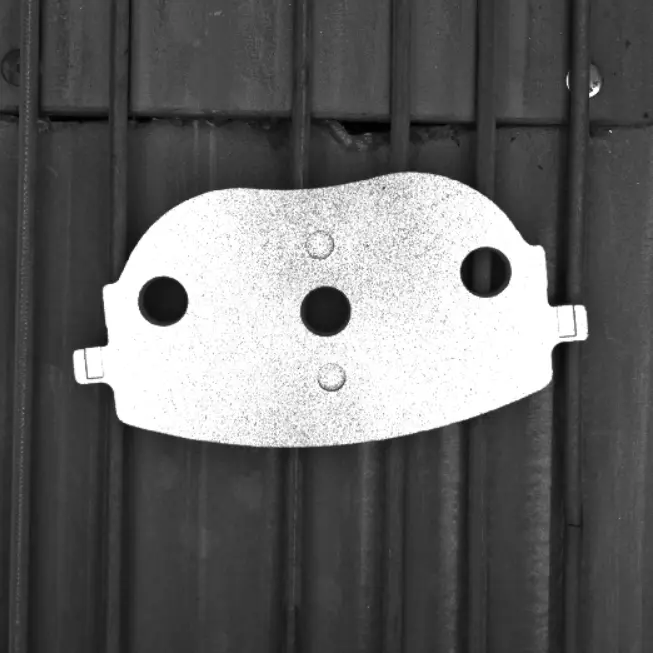

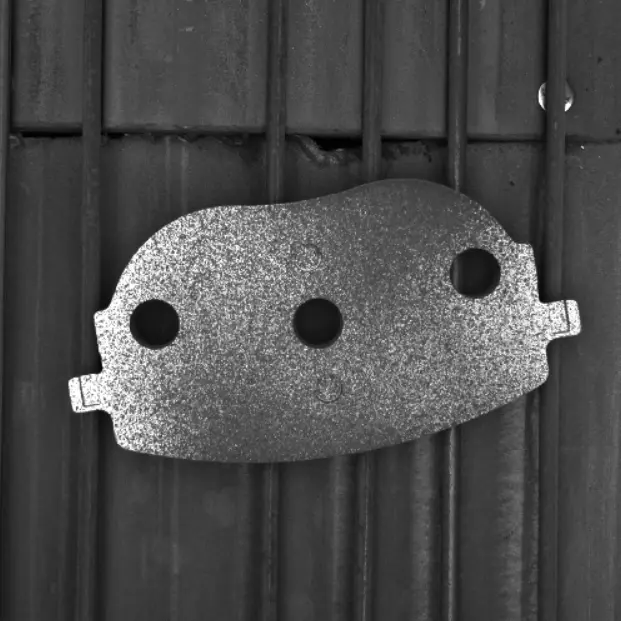

No gluing

Dry gluing

Wet gluing

Adhesive failure

THE METHODOLOGY

To address these challenges, CODA Systems has implemented a customized solution that combines advanced technology with adaptation to industrial conditions:

- Caméra matricielle haute vitesse monochrome 5 mégapixels, installée directement sur la ligne de production.

- Light box with filtered air supply, protecting the viewing station against contamination (dust, vapors) and ensuring image stability.

- Éclairage dôme plat, garantissant une répartition uniforme de la lumière et une détection optimale des défauts.

- Intelligent system for adapting to ambient dirt levels, allowing for precise detection even in extreme conditions.

- Defect detection capability up to 1 mm², ensuring precise identification of anomalies.

THE RESULTS

Thanks to this innovative solution, the automotive manufacturer now benefits from 100% quality control of brake pads, ensuring total compliance and avoiding risks related to manufacturing defects. The benefits are numerous:

The benefits are numerous:

- Process optimization: elimination of errors and improvement of the production flow.

- Customized HMI interface: clear and intuitive display of information for simplified understanding of results.

- Training and skill development of technicians: the operators have been trained in the use of the system and the interpretation of results. The line operators set the defect thresholds themselves, avoiding time-consuming manual checks.

- High satisfaction: the solution provides real added value and perfectly meets the client's requirements.

The integration of this industrial vision technology allows this automotive parts manufacturer to optimize its quality control and ensure the reliability of its products. At CODA Systems, we design solutions tailored to the most demanding industrial environments, combining precision, performance, and ease of use.

ANY QUESTIONS?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA