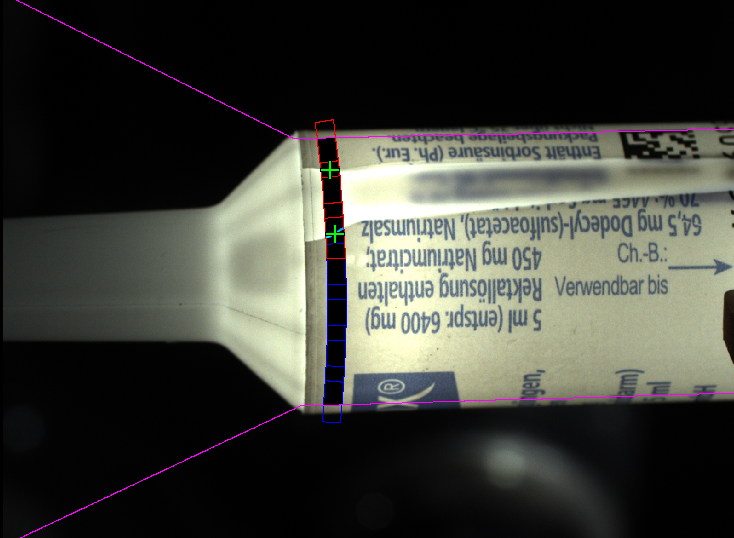

APPEARANCE CONTROL ON

PHARMACEUTICAL TUBES

In the pharmaceutical sector, quality is not just a requirement: it is an obligation. Each component, packaging, and step in the production process must meet strict standards to ensure safety and compliance imposed by regulations such as ISO 9001 and ISO 15378. Manufacturers must continuously optimize their automated quality control methods.

THE CHALLENGE

Our client initially contacted CODA Systems to optimize an existing Keyence CV-X vision inspection system in their factory. However, this system did not allow for proper appearance inspection of the tubes, as they could arrive with variable positions and angles. This was a situation that the CV-X system could not handle correctly. As a result, the inspections were incomplete or incorrect.

On the pharmaceutical tubes, the client needed :

- Detect the absence of overmolding (drips)

- Check the presence and positioning of the label

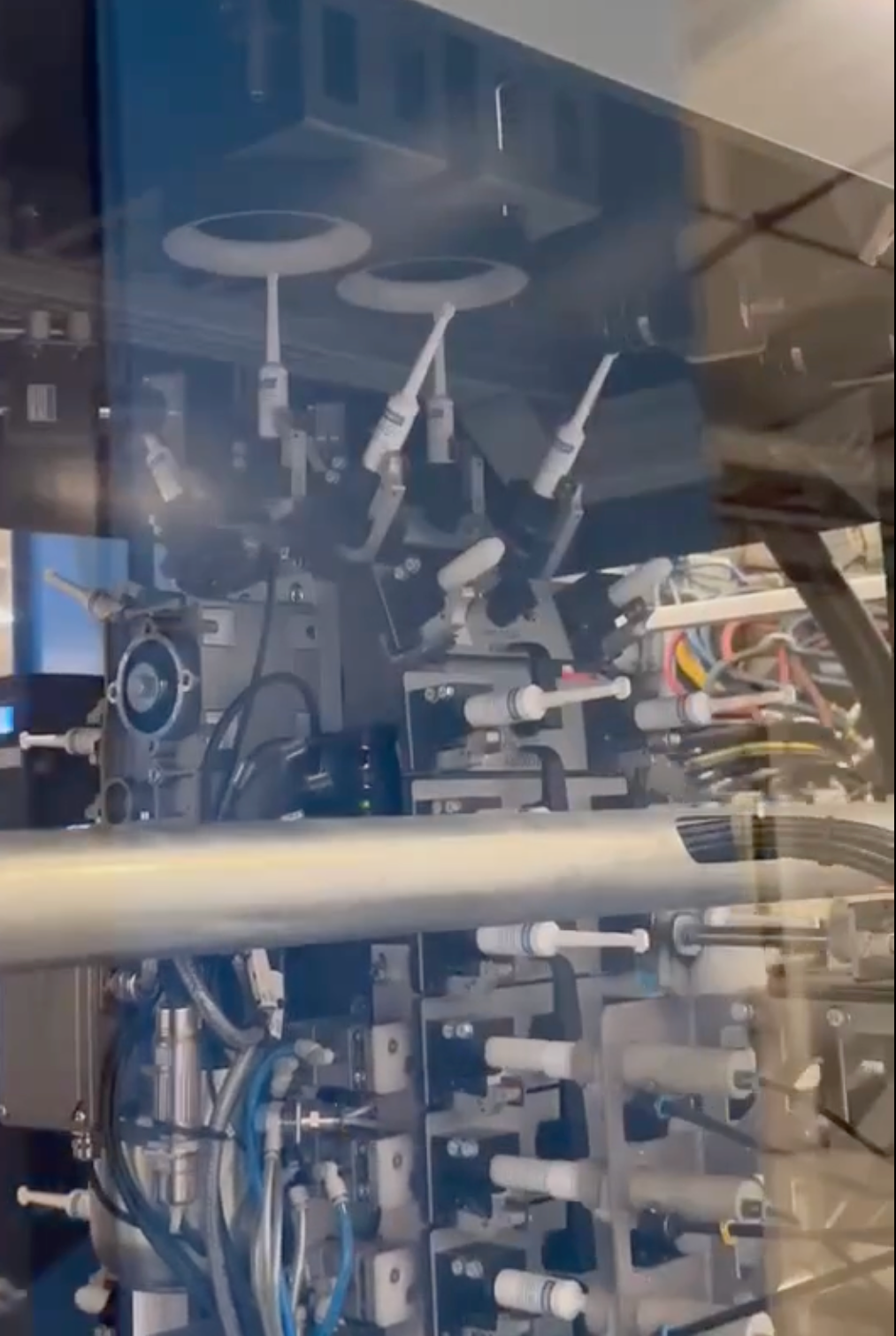

To meet these requirements, CODA Systems recommended installing a Keyence XG-X system. This industrial vision camera is capable of automatically adjusting the inspection area based on the actual orientation of the tube in each image.

PROJECT COMPLEXITY

- Variable tube orientation: since the tube positioning is not repeatable, the inspection area had to be adjusted automatically on a frame-by-frame basis.

- High speed: 100 tubes/minute. The new program had to be integrated without slowing down the production rate.

- Multiple tube references

The client should be able to:

- Add new references,

- Modify the control criteria,

Everything in total autonomy.

METHODOLOGY

- Selection of a new industrial vision system: transition from CV-X to XG-X

Following a thorough feasibility study in our laboratory, the implementation of a new image processing system proved necessary. Its ability to manage dynamic inspection areas adapted to variations in tube position allowed us to meet customer needs.

- Creation of a customized HMI

CODA Systems has developed a dedicated interface that allows the client to add new references and modify control queries without the intervention of a CODA expert.

RESULTS

- Reduction of the scrap rate: initially from 4% to less than 1%

- Client completely autonomous for the management and evolution of controls, without the need for external assistance and additional costs.

ANY QUESTIONS?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA