AERONAUTICS & DEFENSE

With increased demands for precision and reliability, these industries cannot afford to compromise on ultra-precision. Automated quality control allows for the detection and elimination of defects before they affect finished products, thereby preserving the brand image of companies. By reducing non-conformities, industrial vision enhances safety, strengthens customer trust, and optimizes the overall performance of production processes.

EXAMPLES OF USE CASES

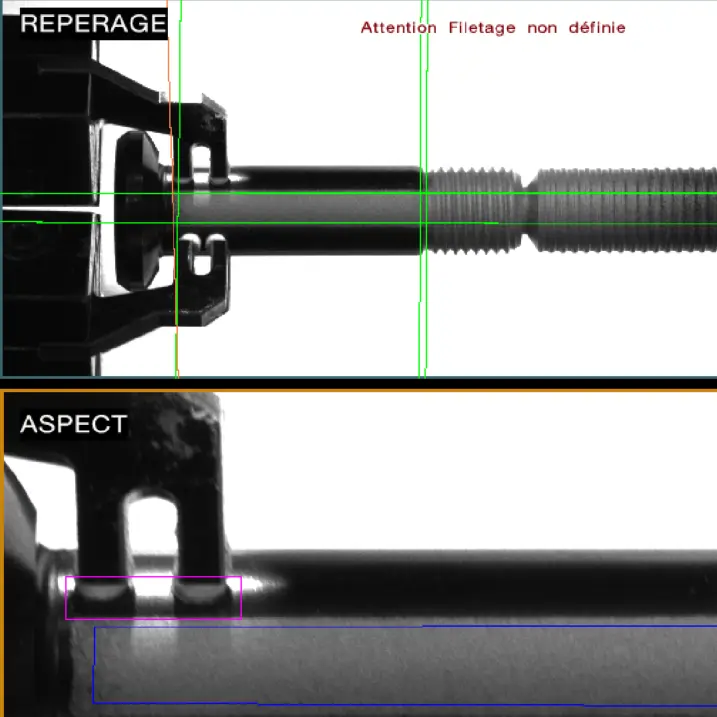

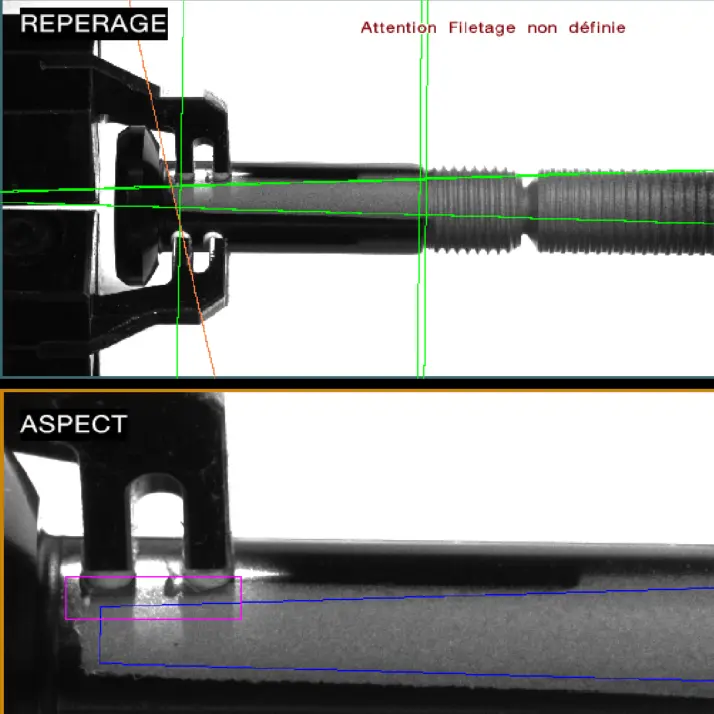

AERONAUTICAL RIVET INSPECTION

AERONAUTICAL SHEATH FORMING PROCESS CONTROL

OPTICAL ELEMENT POLLUTION CONTROL

CONTROL OF THE APPEARANCE OF CARBON AERONAUTICAL CONNECTORS

QUALITY CONTROL OF LASER CUTTING IN ROLLING

ROBOT GUIDANCE BY VISION FOR AUTOMATIC SCREWING OF AERONAUTICAL COMPONENTS

WELD BEAD INTEGRITY CONTROL ON SPACE COMPONENT

OUR REFERENCES IN AERONAUTICS AND DEFENSE

ANY QUESTIONS?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA