AUTOMATE YOUR QUALITY CONTROLS THANKS TO INDUSTRIAL VISION INSPECTION

Industrial vision inspection today enables the reliability and acceleration of quality control in almost all industrial sectors. Thanks to increasingly advanced image processing systems, it is possible to detect defects that are invisible to the naked eye, avoid non-conformities, and improve traceability — all in real-time and without contact.

OUR SUPPORT

At CODA Systems, we support you from A to Z in implementing your industrial vision quality control solutions. Depending on your level of expertise, we assist you in selecting the equipment with real-world testing and in training your teams to enhance their skills on your vision systems.

WHAT IS INDUSTRIAL VISION INSPECTION?

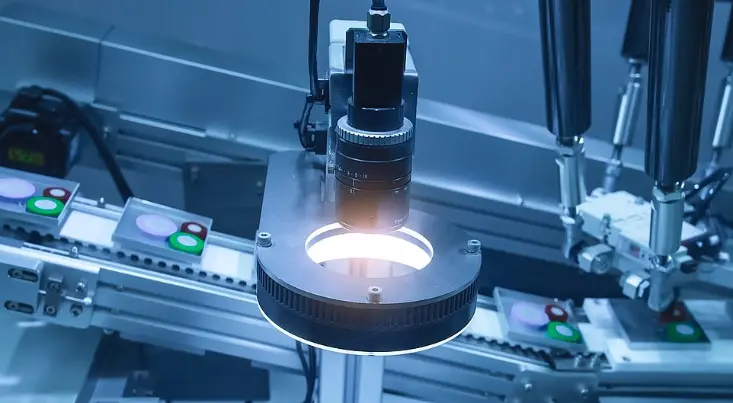

Industrial vision inspection relies on the use of a camera combined with an image processing system. The goal is to capture images of parts or products, and then automatically analyze these images to validate (or not) their conformity. This inspection is directly integrated into the production line, allowing for high production rates while ensuring a consistent level of quality.

Industrial vision inspection occurs at different stages of manufacturing: directly on your production line at a crucial step or at the "line edge" for more specific control.

THE MAIN APPLICATIONS OF INDUSTRIAL VISION INSPECTION

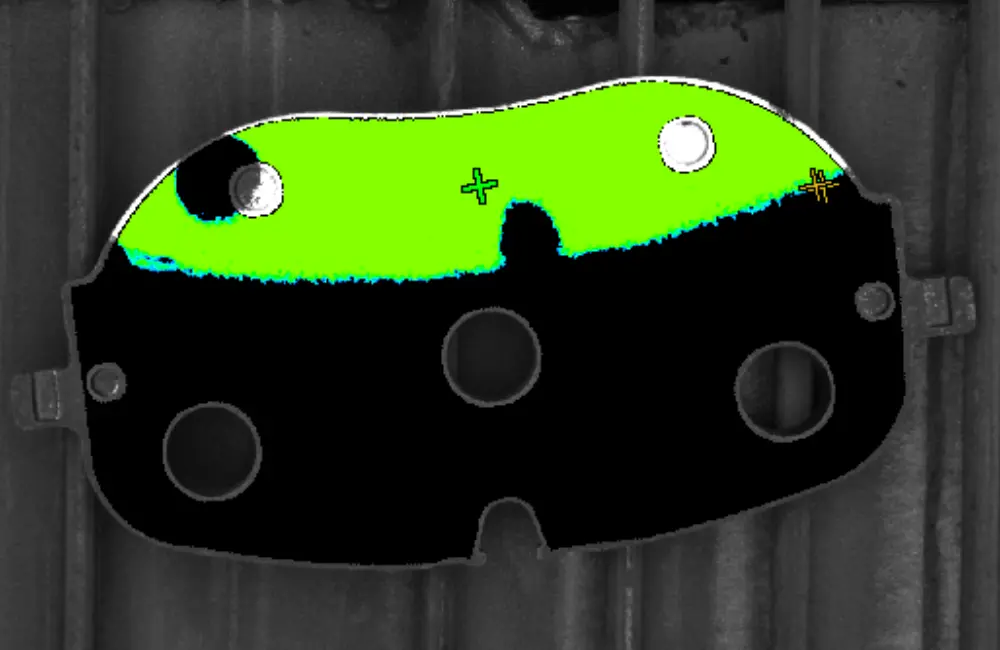

The heart of inspection lies in the ability to process captured images. An effective industrial vision solution not only detects defects but also classifies them, tracks data, and interacts with other systems on the production line.

PRESENCE/ABSENCE

Check if all expected elements are present (e.g., cap on a bottle)

DIMENSIONAL CONTROL

Measure distances, diameters, thicknesses, or angles with great precision.

APPEARANCE CONTROL

Detect scratches, bubbles, stains, smudges, breaks, or any other visual anomalies.

MARKING CONTROL

Ensure that the printed information is correct, legible, and well-positioned.

READING CODES

Read and validate barcodes, datamatrix, or QR codes, often used for logistics tracking.

WHAT EQUIPMENT FOR AN EFFECTIVE INDUSTRIAL VISION INSPECTION?

CHOOSING THE RIGHT INDUSTRIAL VISION CAMERA

The choice of an industrial vision camera directly depends on the intended application. It is necessary to consider the required resolution, the frame rate to be maintained, the working distance, the types of defects to be detected, and the industrial environment. Some cameras are better suited for detecting micro-defects, while others are designed for the rapid capture of moving parts.

LIGHTING, OPTICS, AND SENSORS: ESSENTIAL ELEMENTS

A high-performance vision system is not limited to a good camera. Lighting (directional, diffuse, ring, infrared...) plays a crucial role in image quality. Similarly, the choice of lens and sensor must be suited to the geometry of the inspection and the materials being observed.

ANY QUESTIONS?

If you would like to share a project or need more information, our team is at your disposal.

CONTACT CODA